Industrial Wound Brushes

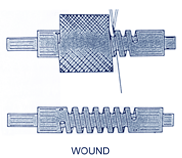

Wound brush construction is a versatile construction used in small and large diameter cylinder brushes. Our Industrial wound brushes use a steel, aluminum, brass, stainless steel or plastic core where a groove is cut in the core helically in the same manner as an acme screw thread. A stainless steel retaining wire then pulls the filaments down into the core and is fastened at the ends. The advantage of this construction is that the filaments and the retaining wire are recessed into the core. This allows for smaller outside diameters and easier refilling.

Wound brush construction is a versatile construction used in small and large diameter cylinder brushes. Our Industrial wound brushes use a steel, aluminum, brass, stainless steel or plastic core where a groove is cut in the core helically in the same manner as an acme screw thread. A stainless steel retaining wire then pulls the filaments down into the core and is fastened at the ends. The advantage of this construction is that the filaments and the retaining wire are recessed into the core. This allows for smaller outside diameters and easier refilling.

When refilling our industrial wound brushes, the central retaining wire is removed and filaments taken out. Industrial brushes are refilled good as new in the same way as they are manufactured at considerable savings. Our industrial wound brushes can be trimmed flat or can be trimmed with a contour, crown, stepped, concave or convex. Industrial wound brushes can be filled with synthetic or natural filaments and small diameter wire.

When refilling our industrial wound brushes, the central retaining wire is removed and filaments taken out. Industrial brushes are refilled good as new in the same way as they are manufactured at considerable savings. Our industrial wound brushes can be trimmed flat or can be trimmed with a contour, crown, stepped, concave or convex. Industrial wound brushes can be filled with synthetic or natural filaments and small diameter wire.

Industrial brushes can be trimmed flat or can be trimmed with a contour. Brushes can be trimmed with a crown, stepped or concave and convex.

Design Considerations for Industrial Wound Brushes

Designing a brush can be as simple as replacing and improving on an existing brush, or it can require the consideration of a large number of variables that need to be investigated before the best brush for a job is recommended.

Jenkins Brush Company, being a full service brush company supplies brushes in all of the major brush constructions including the unique tufted METLKOR construction, wound, staple-set, channel strip, epoxy-set, wire drawn, and twisted-in-wire constructions.