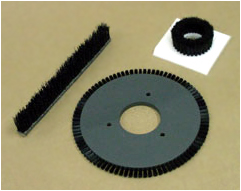

Epoxy Set Brushes

The strongest and sturdiest industrial brushes money can buy are epoxy-set brushes. A single hole is drilled in a substrate, filaments are bundled and dipped in epoxy and set into the hole and allowed to set up.

Epoxy-set construction is used where maximum filament retention is needed and quantities dictate.

Design Considerations

Designing a brush can be as simple as replacing and improving on an existing brush, or it can require the consideration of a large number of variables that need to be investigated before the best brush for a job is recommended.

Designing a brush can be as simple as replacing and improving on an existing brush, or it can require the consideration of a large number of variables that need to be investigated before the best brush for a job is recommended.

Jenkins Brush Company, being a full service brush company supplies industrial brushes in all of the major brush constructions including the unique tufted METLKOR construction, wound, staple-set, channel strip, epoxy-set, wire drawn, and twisted-in-wire constructions.

Why Use a Tufted Brush?

Wire drawn, staple set and epoxy set brushes are all examples of tufted brushes. Tufted brushes allow for the best cleaning because of their ability to allow the filaments to move in four directions as compared to only two directions as in channel strip type industrial brushes. An extremely wide variety of designs, densities and patterns are available in tufted brushes. The function of the brush determines the tuft size, pattern, fill material and trim length. Patterns can be very dense to very open. Blocks can have their tuft holes angled or flared to allow for specific shapes. Hole patterns can also be designed around mounting fixtures or holes without affecting the brushes function. Industrial brushes can be trimmed flat or can be trimmed with a contour, crown, stepped, concave or convex.