Void – Jenkins Brushes are used to detect voids, holes or spaces in your product. Electric charge passes thru the brush and where the void occurs the electrical circuit is completed. This determines where a hole or void is. The brushes are usually filled with stainless steel or brass fine diameter wire, but other materials can be used.

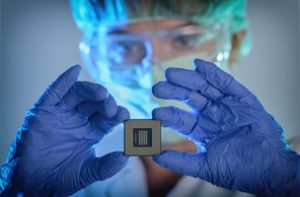

Surface Prep – Jenkins Brushes are used to prepare the surface of wafers or chips before they are etched. Brushes are also used to clean the surface after they are etched.

Anti-Static – When you have applications where static can create a problem, brushes can be used to reduce or remove the static that you are generating. Brushes filled with anti-static material, bristle or natural hair will reduce the amount of static that is generated but not eliminate it. Brushes filled with 100% conductive nylon or wire will remove the charge and direct it towards a known ground.

Cleaning – Brushes are used to clean PC boards, chips and circuits in many different applications. Cleaning of the product helps to remove any contaminants thus allowing for better performance of your products.